Quality – Capability – Reliability

With over 60 years of excellence in machining, our machine shop combines decades of expertise with cutting-edge technology to deliver unmatched precision and quality. Utilizing advanced CAD/CAM capabilities, we ensure that each project is designed and executed with the utmost accuracy and efficiency, from prototypes to full-scale production. As an ISO 9001:2015 certified facility, we are committed to maintaining the highest standards of quality and consistency, making us a trusted partner for businesses across a wide range of industries.

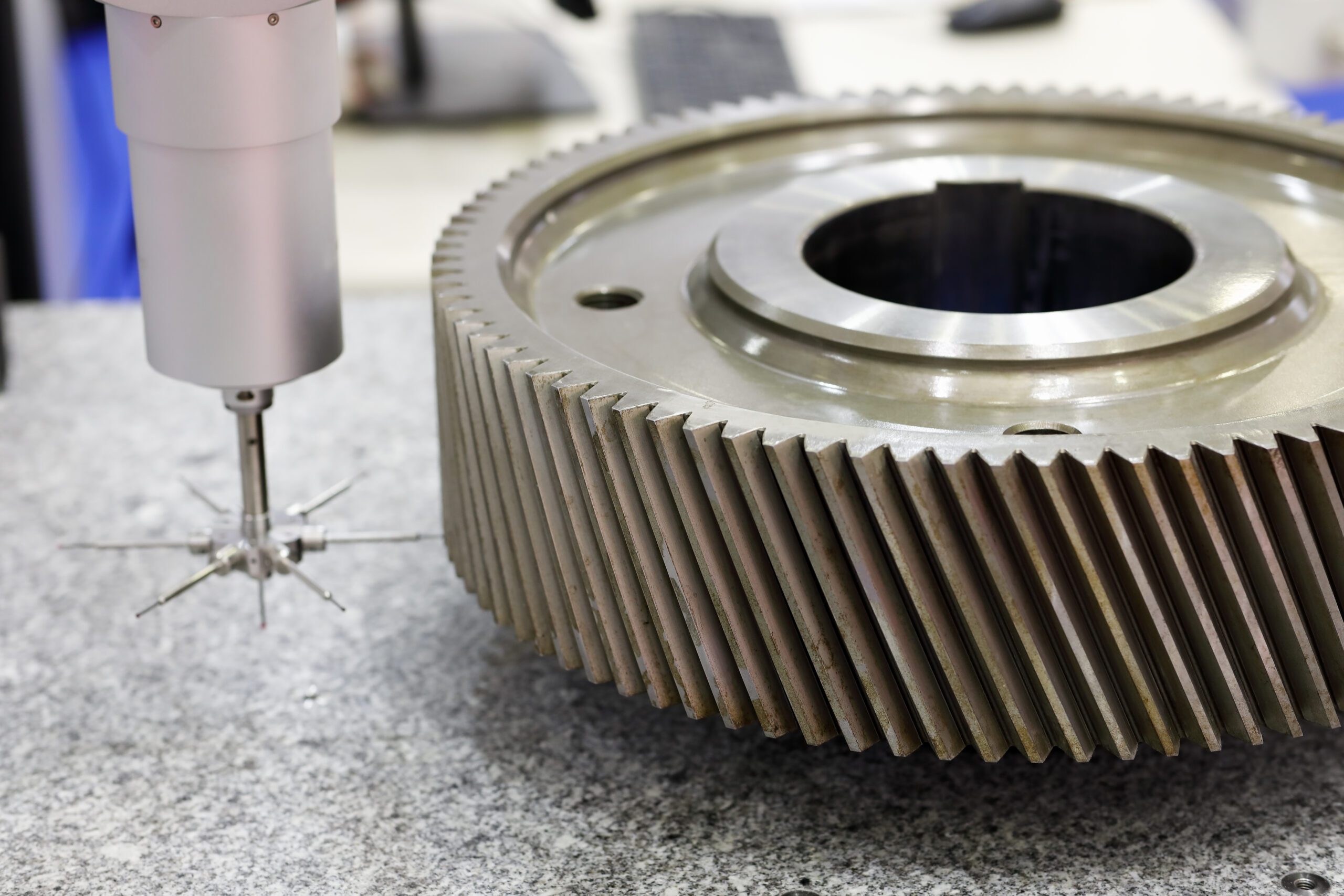

Our state-of-the-art Quality Lab is equipped with advanced tools, including a coordinate measuring machine (CMM) and an optical comparator, to ensure precision and maintain tight tolerances on critical parts.

We pride ourselves on rigorous quality control processes, ensuring every component meets the highest standards. Our lab is also capable of performing all levels of Production Part Approval Process (PPAP) to guarantee that parts are manufactured consistently to meet exact specifications.